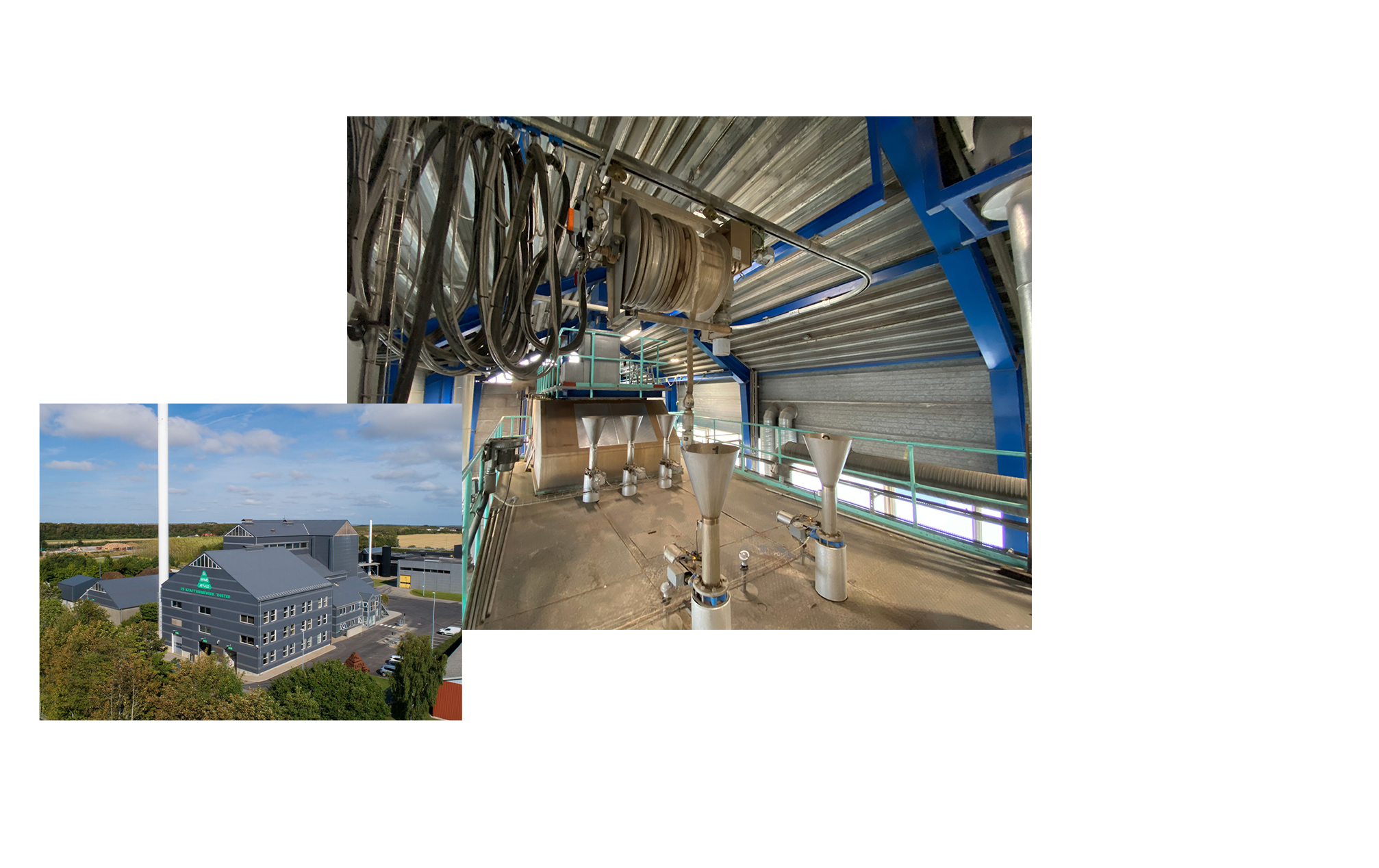

Thisted Cogeneration Plant, Denmark

Overview

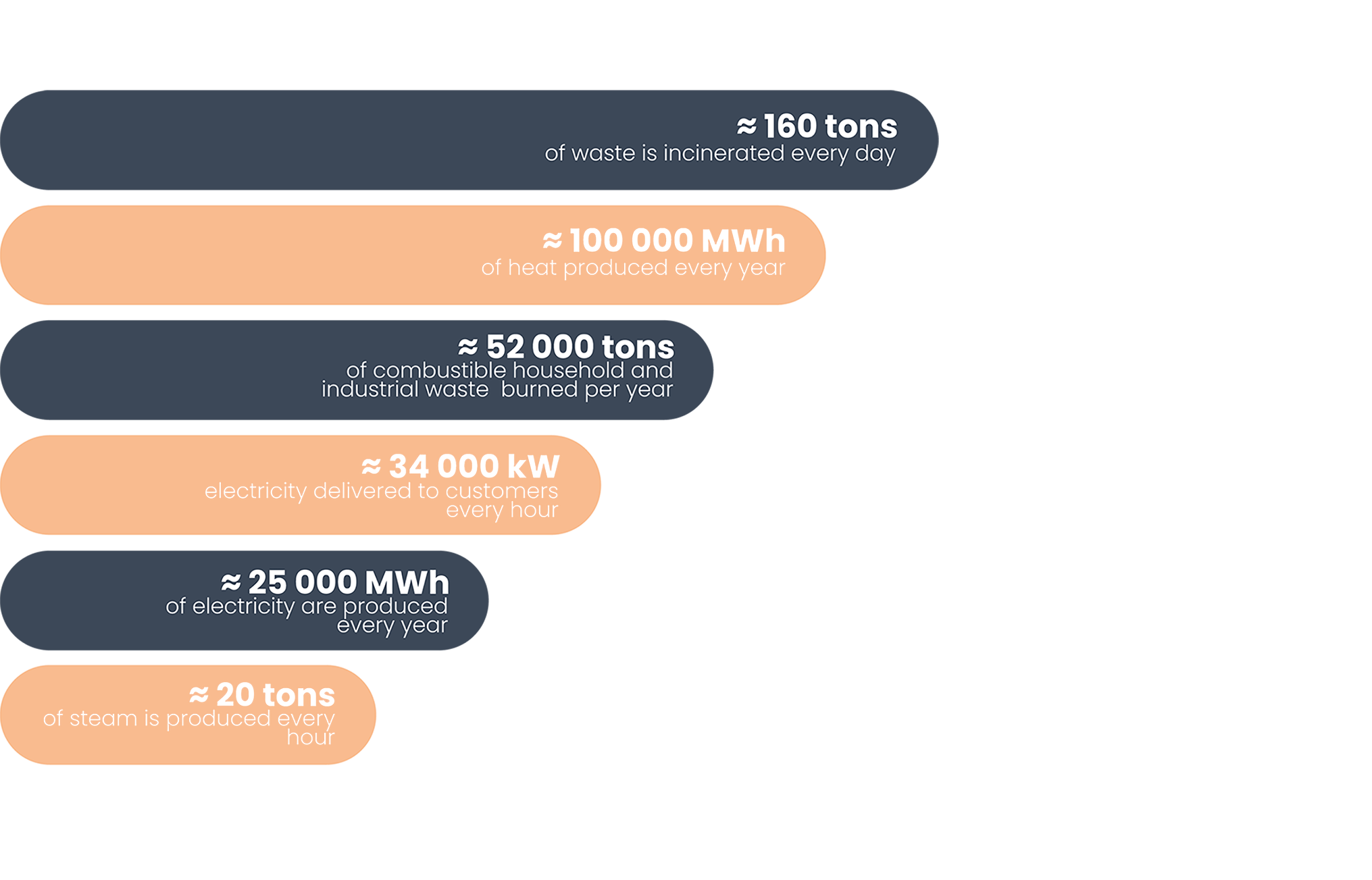

The Cogeneration Plant Thisted is placed in the North/West corner of Denmark and provides district heating and electricity to the city of Thisted. Its fuel source consists of a combination of 52.000 tons of combustible household and industrial waste per year.

The plant produces approximately 100,000MWh of heat and 25.000MWh of electricity on a yearly basis. The electricity produced is then distributed to consumers, delivering a substantial total of 34000kW per hour.

The Cogeneration Plant Thisted uses 22MW waste-to-energy boiler which was brought into operation in 1993. On average the plant incinerates 160 tons of waste a day and produces approximately 20 tons of steam an hour.

Problem

Maintenance of the boiler is crucial at the Thisted Cogeneration Plant and therefore the cleaning process holds paramount significance, as it directly impacts the safe and efficient operation of the facility. With a proper cleaning process of the boiler, it is ensured that hazardous emissions and toxic smoke are eliminated, which might pose significant risks to the facility and its surroundings.

Before the Aerovit Shower Cleaning Solution implementation at Thisted Cogeneration Plant, regular shutdowns and cleanings were necessary every 3 to 4 months, to ensure the efficient operation of the boiler. After cleaning of the boiler, fouling would occur within two months, causing a decrease in heat transfer efficiency. Consequently, the plant’s overall performance suffered and energy consumption increased. To address these issues and improve heat transfer efficiency, it was essential to implement periodic shutdowns and cleanings. On the average the cleaning process took approximately 4 to 5 days.

Solution – Aerovit Shower Cleaning

The Cogeneration Plant Thisted implemented the Aerovit Shower Cleaning Solution – SC-Jet system, which has proven to be highly efficient in reducing the frequency of shutdowns.

Since the introduction of the Aerovit Shower Cleaning Solution, the boiler has been able to operate seamlessly throughout an entire year without requiring any cleaning shutdowns.

Furthermore, this implementation has resulted in a remarkable enhancement of the boiler efficiency. As a consequence, the boiler now generates a significantly higher output of megawatts per year, thereby increasing its overall productivity and reliability.

Statement from Thisted Cogeneration Plant

How does the Aerovit Shower Cleaning work?

Aerovit Shower Cleaning Solution is an online cleaning solution that has significant capability to operate effectively at high temperatures. In the Thisted Cogeneration Plant the temperature in the boiler when boiler cleaning is initiated is 625-630°C degrees.

Cleaning is performed by lowering the SC-Jet patented nozzle head down into the boiler’s core 3-4 times a day in various places of the boiler. Then during the full-load operation of the incinerator, an optimal quantity of water is precisely sprayed onto the heated central core walls, effectively removing the slagger deposits. This process ensures efficient performance and is executed with precision. Current boiler cleaning expenses are 20 000 DKK a year.

Download case

If you want further information about the case you can find it here