Orlén Refinery, Lithuania

Situation BEFORE Aerovit Installation

Orlen Lietuva Refinery has two boilers which are losing a considerable amount of heat due to catalyst dust build-up in the tubes. After two month of operation the boilers tubes are fully covered by catalysts dust, but Orlen ́s technicians cannot stop them for manual cleaning because it would imply the whole refinery to shut down.

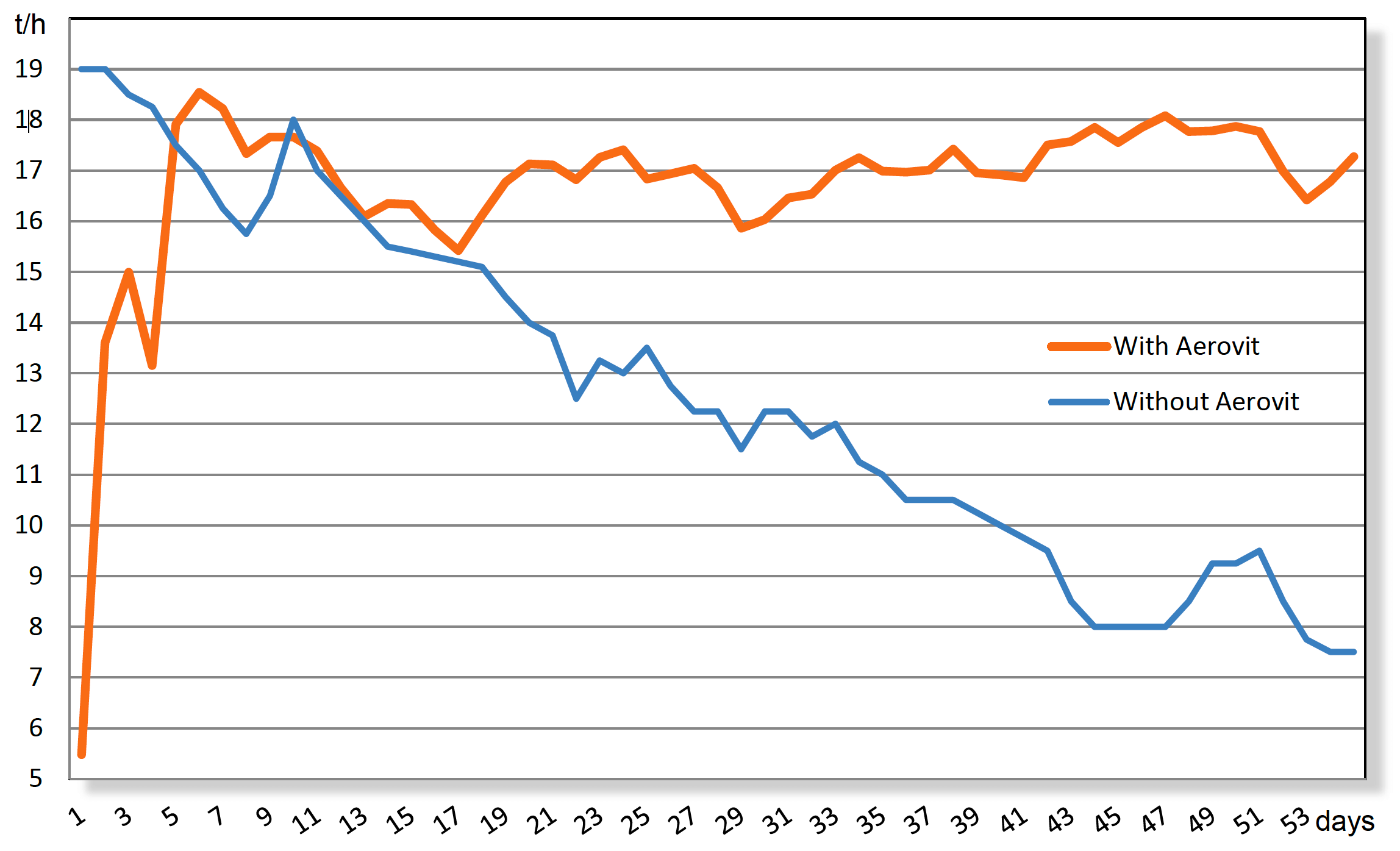

The diagram shows the steam production of one boiler: after a manual cleaning session the steam production is about 19t/h and after two months it is only 7,5t/h.

The final result of the dust accumulation process is a critical reduction of the steam production, which after two months of operation decreases to 15t/h for both boilers.

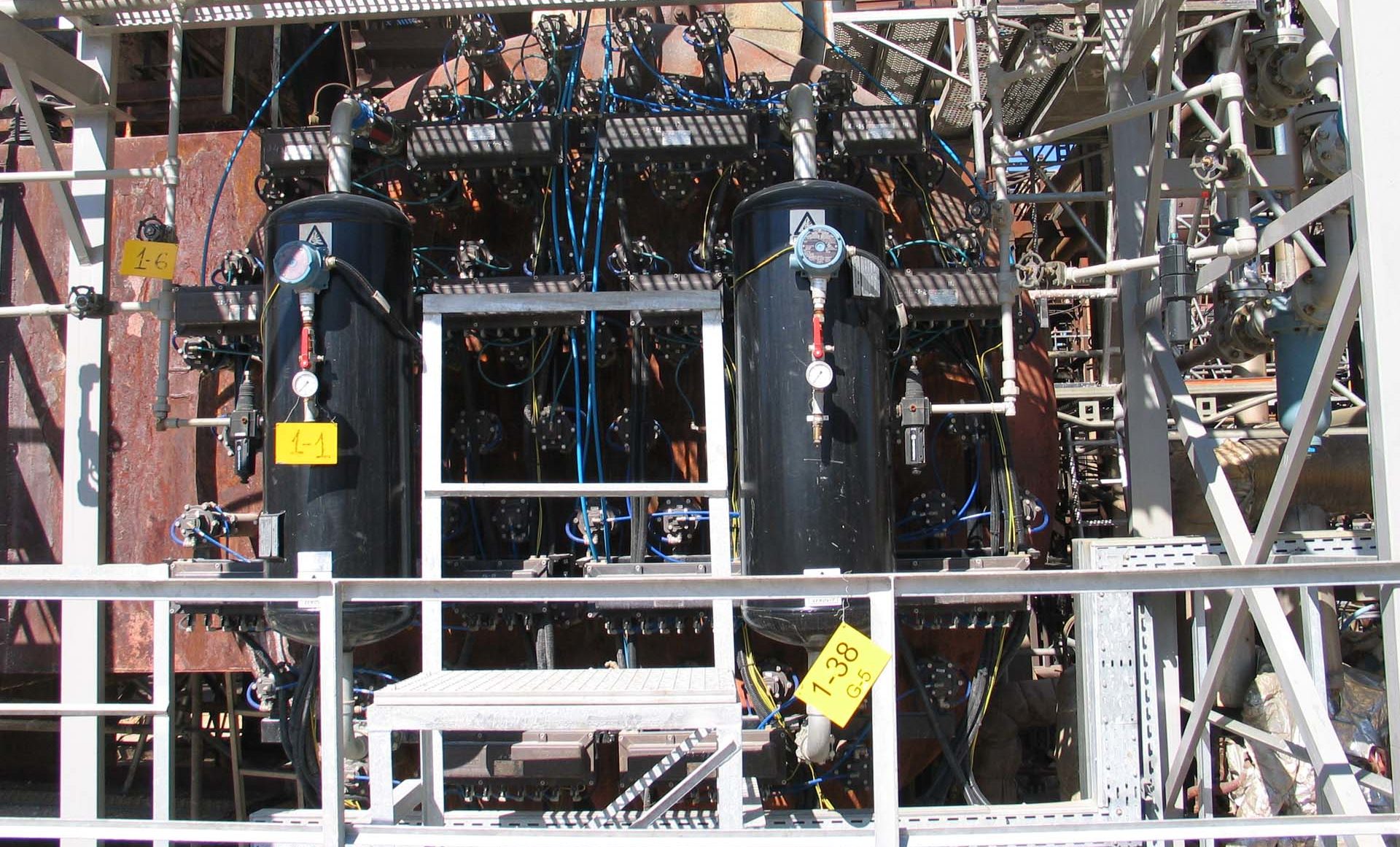

Situation AFTER Aerovit Installation

AEROVIT is installed in April 2011 on both boilers with immediate results. The steam production of each boiler remains stable around 17t/h, which means 34t/h for both boilers. Orlen ´s gain therefore is 19t/h for both boilers. In order to produce these 19t/h steam on an oil boiler, Orlen should use around 11,6 mio. Litre of oil/year.

Download case

If you want further information about the case you can find it here