Hasselager, Denmark

- Installation

Waste-fired factory with increased emission and environmental requirements. - Fuel

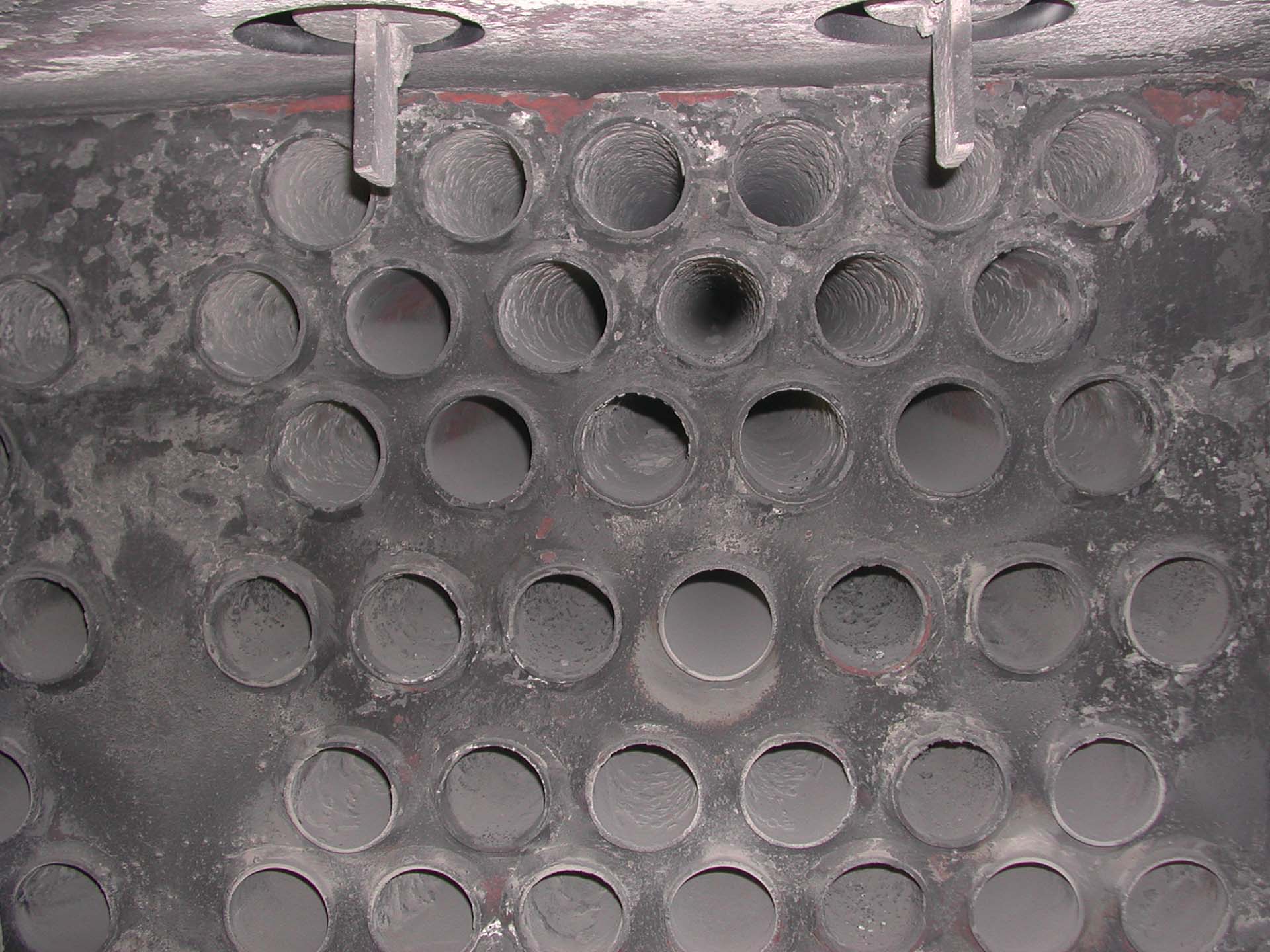

Mixture of seed and grain as well as feedstuff residue, dust, chaff, whole grain and pressed grain. - Boiler

Danstoker Multimiser No. 19, which is a 5-pass hot-water boiler with a 2 MW output. The boiler was installed in 2001.

The problematic fuel meant that the boiler needed to be cleaned manually for every 14 days of operation because of heavy deposits in the tube passes. The decision was consequently made to retrofit the AEROVIT system in December 2002.

Without Aerovit

26 Manual cleaning per year.

Manual cleaning, 8 hours every 14 days. Downtime: 24 hours for each boiler cleaning.

With Aerovit

4 manually cleanings per year.

After installation of AEROVIT: Four times annually, 90 minutes each.

Gained operating time 528 operating hours ~ saving of 84.6%.

Gained working hours: 202 working hours ~ saving of 97.1%.

Annual efficiency

AEROVIT increases the annual efficiency of the installation by approx. 8 %.

Investment

It cost 170.000 DKK to install the AEROVIT system.

Payback time

The investment is made back in approx. 6 months.

Download case

If you want further information about the case you can find it here